Status : Completed

Tags: OpenCV Python Tkinter TensorFlow NumPy and Panda Deep Learning Framework

To automate the identification and classification of defects in manufactured products, ensuring quality, reducing costs, and enhancing customer satisfaction.

Python

NumPy and Panda

OpenCV

TensorFlow

Deep Learning Framework

Tkinter

Aim :

The aim of a defect product detection project using AI and ML typically revolves around developing a system capable of automatically identifying and categorizing defects or anomalies in manufactured products.

Tech stack :

● Tensorflow

● OpenCV-python

● CNN

Also, a dataset will be required to train a new model if not using pre-trained .

Introduction :

This project aims to revolutionize quality control in manufacturing by employing Artificial Intelligence (AI) and Machine Learning (ML) techniques for automated defect detection. Traditional methods often struggle with accuracy and efficiency in identifying defects, leading to increased production costs and compromised product quality. Leveraging AI/ML, this project endeavors to develop a robust system capable of accurately detecting and categorizing defects in manufactured products. The goal is to enhance quality control, reduce costs, and improve overall production efficiency.

Features :

Detailed breakdown of project components:

Working :

1. Data Collection: The system requires a vast amount of data to train a robust machine learning or deep learning model. This data will consist of images, videos, or sensor data of both defective and non defective products.

2. Machine Learning/Deep Learning Model: The heart of the project is a sophisticated machine learning or deep learning model. Convolutional Neural Networks (CNNs) are commonly used for imagebased defect detection tasks due to their ability to extract relevant features from images effectively.

3. Training: The model is trained using the pre-processed dataset, where it learns to differentiate between defective and non-defective products.

4. Model Evaluation: The trained model's performance is evaluated using a separate dataset that it has not seen during training.

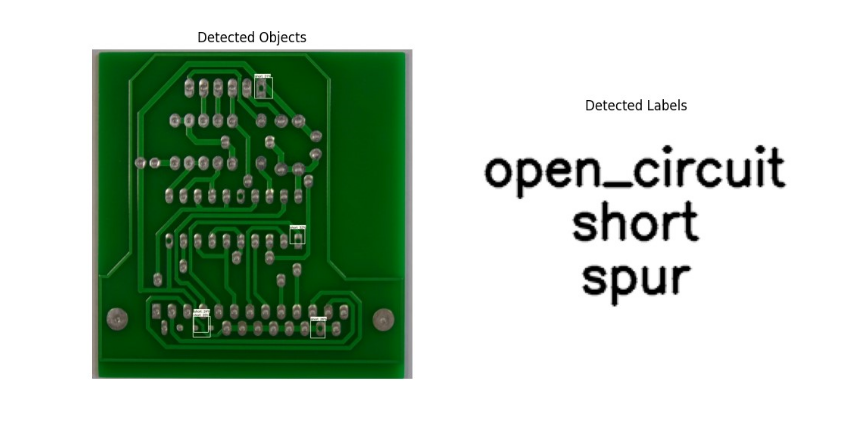

5. Defect Classification: The system can classify defects into different categories to help manufacturers understand the nature of the defects and take appropriate corrective actions.

6. Real-time Detection: In a production environment, the system should be able to analyze product images or data in real-time, providing immediate feedback on the quality of each product. This ensures that defective products are detected and removed from the production line promptly.

7. Continuous Learning: To adapt to new defects or variations in production processes, the system may incorporate mechanisms for continuous learning. This enables the model to update and improve its defect detection capabilities over time.

Methodology :

Methodology for a defect product detection project using AI and ML:

1. Problem Understanding:

2. Data Collection and Preparation:

3. Model Development:

4. Model Evaluation:

5. Deployment and Integration:

6. Monitoring and Maintenance:

7. Documentation and Reporting:

Workflow diagram :

Video Link : https://youtu.be/741qKtR5D8E

Resources :

Real-life applications :

Problem faced :

Common challenges encountered in defect product detection projects using AI/ML include:

Data Quality and Quantity: Insufficient or unbalanced datasets, requiring extensive cleaning and augmentation to train accurate models.

Model Complexity: Developing intricate models prone to overfitting or lacking generalization across various defect types or production conditions.

Integration Complexity: Challenges integrating AI/ML systems into existing manufacturing processes, requiring seamless compatibility and real-time functionality.

Performance Metrics: Difficulty in achieving desired accuracy or precision, impacting the system's reliability in defect identification.

Scalability and Adaptability: Ensuring models can handle diverse product ranges and evolving defect patterns without compromising accuracy or speed.

Resource Limitations: Constraints in computational power, time, or expertise affecting model training, deployment, and maintenance.

Real-time Constraints: Balancing the need for quick defect identification with computational speed to avoid production delays.

Contributors:

TEAM 1:

|

S.No |

Name |

Branch |

Reg. No. |

|

1- |

Kushagra Verma |

ECE |

20224089 |

|

2- |

Kavya Gupta |

ME |

20226074 |

|

3- |

Rohit Singh |

CSE |

20223216 |

|

4- |

Ashutosh Madheshiya |

ME |

20226034 |

TEAM 2:

|

1 |

Rohit singh |

CSE |

20223216 |

|

2 |

Ashutosh Madhesia |

ME |

20226034 |

|

3 |

Yashita Yadav |

PIE |

20227060 |

|

4 |

Yogesh yadav |

ME |

20222066 |

|

5 |

Jain Chaudhary |

ECE |

20224073 |

Mentors:

1. Shashank Singh Final Year

2. Kandukuri Yashwanth Final Year

3. Rishi Mishra Pre- Final Year

4- Bhanu Pratap Singh Pre- Final Year

Thank you

Team Defect Product Detection