Status : Completed

Tags: Arduino Smart solar panel CAD desiging LDR

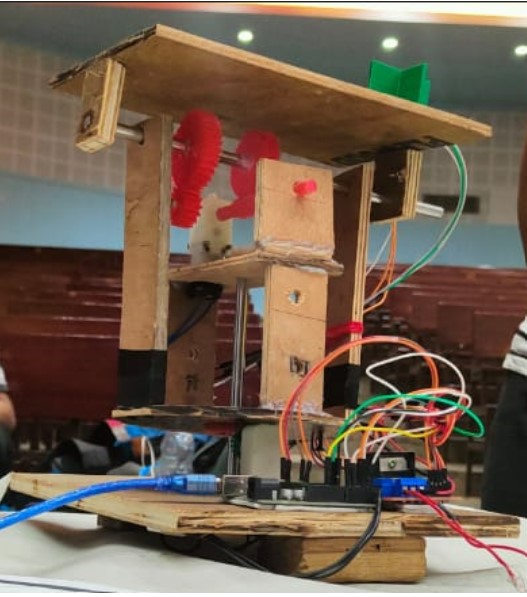

To make a rotating solar panel that rotates in the direction of maximum light intensity.

Arduino

LDR

Dual axis solar tracker

To make a rotating solar panel that rotates in the direction of maximum light intensity.

The mean monthly value of the intensity of direct solar radiation normal to the solar beam received at the earth’s surface at noon time in India varies from 0.51 to 1.05 Kw/m2, depending on latitude, altitude, and season. This solar energy can be harnessed by designing a smart solar panel consisting of a geared system driven by a motor that rotates the panel at the same speed as the earth’s rotation (about 15 degrees per hour). The radiation falling on a surface is absorbed maximum when it falls perpendicular to the surface. This project uses this concept to optimize solar power generation. Further using gears theory, the power is optimized using a low power-consuming motor. A dual-axis tracker rotates the solar panels from East to West and North to South to provide direct exposure to sunlight. The presence of two axes in this tracker, i.e., the primary axis and secondary axis, facilitate convenient movement of the solar panels in all directions.

The most attractive feature of this device is that it helps generate nearly 40% more power than a fixed solar panel.

MPPT(maximum power point tracking) Algorithm: It Involves continuously adjusting the orientation of the solar panel to ensure it captures the maximum amount of sunlight. LDR sensors are used to measure the intensity of light.

Sensors: used to measure relevant parameters, such as solar irradiance, panel temperature, and panel voltage/current. These sensors provide data to the MPPT algorithm, enabling it to make informed decisions.

Maximum and Minimum Position Values: The microcontroller determines the maximum and minimum position values beyond which the panel is considered to be in an extreme position. If the potentiometer readings exceed these limits, the microcontroller switches off the DC motor to prevent further rotation.

Dual H bridge motor driver(L298N):

A dual H-Bridge motor driver allows speed and direction control of two DC motors simultaneously. The module can drive DC motors with voltages between 5 and 35V, with a peak current of up to 2A.

DC motor:

DC motors are electric motors that convert direct current electrical energy into mechanical energy. Here it is used to give rotation to the plate.

Arduino UNO:

It is an open-source microcontroller board based on the Microchip ATmega328P. The board is equipped with digital and analog input/output (I/O) pins that may be interfaced with various expansion boards (shields) and other circuits.

LDR (Light Dependent Resistor):

LDR (Light Dependent Resistor) as the name states is a special type of resistor that works on the photoconductivity principle that means resistance changes according to the intensity of light. Its resistance decreases with an increase in the intensity of light. It is often used as a light sensor, light meter, Automatic street light, and in areas where we need to have light sensitivity. It is also called a Light Sensor.

Potentiometer:

The potentiometer is a device that is used to measure the voltage or electric potential. It provides a variable resistance when the shaft of the device is turned. Here, we will measure the amount of resistance as an analog value produced by the potentiometer. We will connect the potentiometer to the Arduino UNO board and will measure the state of the potentiometer. The required code will be uploaded from our computer to the Arduino board.

Spur Gear:

Spur gears are cylindrically shaped toothed components used in industrial equipment to transfer mechanical motion as well as control speed, power, and torque.

Bevel Gear:

A bevel gearbox is a device used to transmit and/or split/distribute the power of a singular rotating mechanical drive shaft through a defined angle, typically 90°.

Worm Gear:

A worm gear is a type of staggered shaft gear that transmits motion between two shafts that are neither intersecting nor parallel. Even though it is compact it can provide a large speed reduction.

This project is an Arduino-based sun-tracking solar panel. The solar panel is connected to a DC motor driven by a motor driver. The DC motor rotates the solar panel.

The Arduino Uno is programmed in such a way that it rotates the solar panel with the help of a dc motor in the direction of maximum solar radiation by detecting it using LDR (Light Dependent Resistors).

The intensity of light is measured by Arduino using LDRs and the intensity of light falling on both LDRs is compared. Based on the comparison signal is given to the dc motor to cause movement. The solar panel turns towards the direction where the intensity of light is more.

A light-dependent resistor is made up of a semiconductor material such as cadmium sulfide or cadmium selenide.

The semiconductor is sandwiched between two electrodes, and when light falls on the semiconductor material, it excites electrons which allow them to move freely and reduce the resistance of the material.

We made use of a potentiometer to limit the angle of rotation of the panel so that it does not take irrelevant orientations. Spur gear was used with a potentiometer to obtain the desired results.

Bevel gear was used to rotate the vertical rod whereas worm gear was used to hold the panel in a particular orientation.

when dc motor is used

when servo motor is used

🔗 Video demonstration //////////// change it

How to Make Solar Tracker System using Arduino and LDR | Arduino based Sun Tracking Solar Panel

How To Make Solar Tracker using Arduino full tutorial | Dual Axis Solar Tracker | Experimentalist

Dual Axis Solar Tracker | Free Download | Prototype Project | For Engineering Students

For Arduino: https://youtube.com/playlist?list=PLV3C-t_tgjGFyXP_-AF37AoIuxM9jzELM

For Solidworks:

https://youtube.com/playlist?list=PLRhna5_X7uWvUg0NTCEwYOUrWcTmVAOfT

Draw and Simulate Bevel Gear Motion | SolidWorks Tutorial

• Agriculture: Solar tracking systems can be beneficial in agriculture, particularly for greenhouse operations. By adjusting the angle of solar panels, these systems can regulate the amount of sunlight entering the greenhouse, optimizing plant growth conditions and increasing crop yields.

|

Name |

Branch |

Reg. no. |

|

Amit Kumar |

ME |

20213051 |

|

Rahul Vinod Kela |

ECE |

20215013 |

|

Pragya Tripathi |

ME |

20213098 |

|

Uttam Kumar Gupta |

ME |

20213050 |

|

Name |

Branch |

Reg.no. |

|

Purushotam Kumar Agrawal |

EE |

20192042 |

|

Abhishek Hanotiya |

ME |

20203005 |

Thank you,

Team - Smart solar panel